HOW TO MAKE A ANALOG

ROBOT ?

We all love watching robot and playing with them. In films

Transformers, Terminator top in our list. This article will give you a

preliminary knowledge about how to make a robot by yourself . Building a robot

is not very troublesome if you stick to the basic of Analog. Problem arises

when it comes to wireless, matching the frequency and ability of the antenna to

transmit that is quite a tedious job, but here there is no need to care about that .

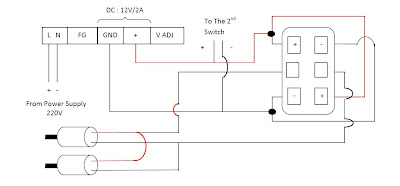

Lets come to the point , for a perfect functioning of a

analog robot , one need constant voltage supply. Variation of voltage or less

voltage will give low power to drive the gear motors. So the first thing you

need is a SMPS or Switch Mode Power Supply.

A SMPS is an electronic power supply that incorporates a

switching regulator in order to be highly efficient in conversion of electrical

power. Like other types of power supplies , an SMPS transfers power from a

source like electrical power grid to a load while converting voltage and

current characteristics. Ideally , a

SMPS dissipates no power ,in contrast

regular power supply regulates the output voltage by constant dissipating power

in pass transistor. This power conversion efficiency is a important characteristic

of SMPS.

Here I have used a SMPS of rating 12V/2A.

Other things that I need:-

1.

A Platform.

2.

4 Tires

3.

4 Gear Motors

4.

2 Switch having 6 terminals

5.

Wires

Platform:-

Tire:-

Gear Motor :-

Here I have used gear motor but we

can also use Servo Motor.

Switch

:-

Wires

:-

The main connection lies with the

SMPS. There are 5 slots in SMPS

1. Live

(L)

2. Neutral

(N)

3. FG

AC

4. DC:

12V/2A

(i)

GND

(ii)

+

5. V

ADJ